Short circuit is a phenomenon that often occurs in electrical appliances. It is a major safety production accident. Sparks will erupt after a short circuit. Therefore, many fires are caused by aging circuits and short circuits, as well as short circuits in electrical appliances, such as home TVs. Household appliances such as air conditioners, air conditioners, refrigerators, etc. in the enterprise are all kinds of production equipment. No matter where there is a short-circuit phenomenon, if the electrical appliance is destroyed, it will cause a fire and explosion. Therefore, preventing the short-circuit phenomenon is very important for the enterprise and the family. important.

There are three types of short circuits in electrical equipment, including power supply short circuits, electrical short circuits, and three-phase system short circuits. There are many reasons for short circuits, such as component damage, weather conditions, man-made damage, and other reasons such as trenching to damage cables, birds and beasts. It is connected across bare current-carrying conductors and so on. There are also many reasons for short circuits caused by production equipment, such as equipment aging, operating errors, damage by rats and cockroaches, and weather factors. The weather factors are caused by rainy days, humid production environments, and damp production equipment.

Humidity comes from atmospheric precipitation. At this time, the air humidity is saturated, and the ground returns to moisture. Under such an environment, it is inevitable that electrical appliances will get damp. This dampness appears in the production workshop, so it is not surprising that the production equipment is damp.

Since water is a conductor, the power supply is prone to short-circuit phenomenon when the production equipment is damp. Although it seems that it can still be used, it will affect the accuracy of the produced product. If it is serious, it will cause damage or even be burned, which will have a great impact on production. , After all, it is production line now, a device failure will cause the subsequent processes to not proceed smoothly, so it will reduce the production efficiency. This is obviously not what the business owner wants. June and July of each year are the busiest times of the year. As a result, the equipment fails, which will delay a lot of things.

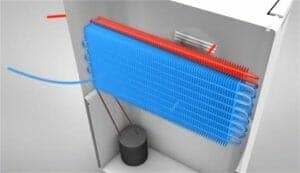

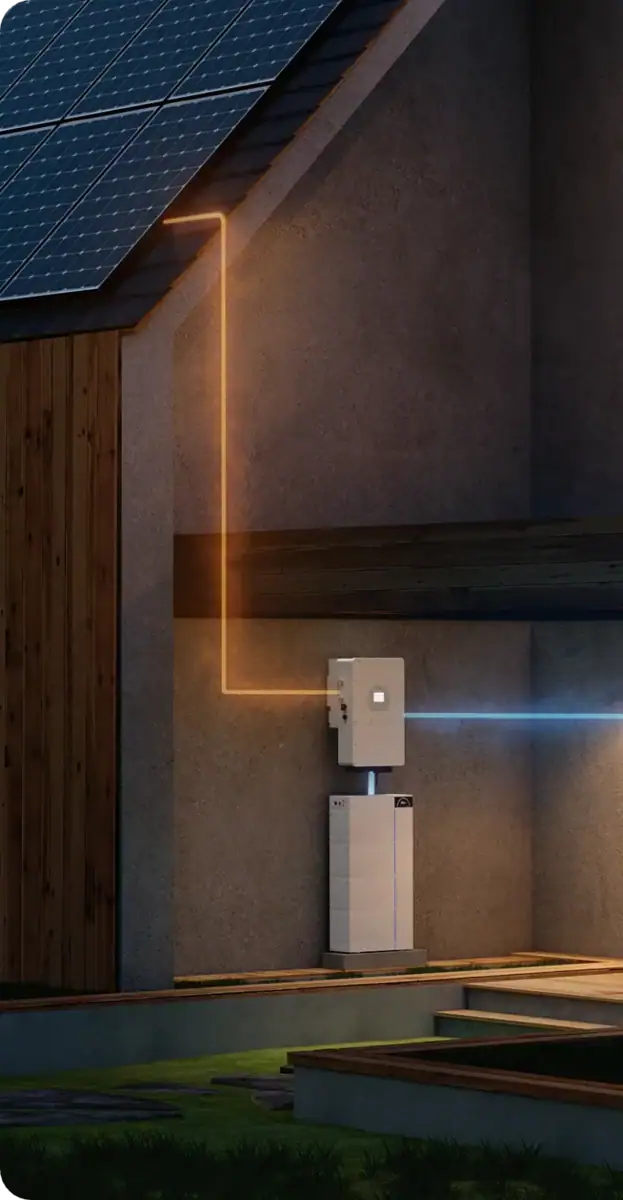

So how to prevent this situation? That is to control the air humidity and prevent the production environment from being humid. This requires professional equipment. Do not use an exhaust fan. It does not hurt to use it when the weather is clear, but when it rains, the humidity of the outdoor air is higher than that of the indoors, and the result is that the indoors are getting more and more humid. Humidity control machine is a professional equipment to remove moisture, also called dehumidifier. It adopts freezing dehumidification technology to quickly reduce air humidity, eliminate moisture, and keep the production workshop dry, so you don’t have to worry about damp failure of production equipment.